In the current manufacturing and engineering environment, companies have complex problems triggering issues like scrap, non-scheduled overtime, poor product performance, and warranty claims, resulting in heavy losses and impacting bottom lines.

Companies may try to solve these complex problems with traditional Root Cause Analysis methodologies, but often the expected results fall short.

The most critical problems are those that ‘have always been there’ and people in these organizations have just learned to live with them. The good news is they don’t have to.

Introduction to the 5 Why Method

Many companies which have successful Lean Manufacturing programs, use a 5 Why interrogative approach for technical problem solving to arrive at a root cause. By starting with the end result or symptoms of a problem and asking “why” a series of times, often the initiating cause can be identified.

This can be a very powerful method since only by understanding the true cause of a problem can the simplest and most effective solutions be flushed out and put into place. However, there are two major challenges with the 5 Why approach:

1.) How to answer why when the answer is not known. Knowing and perceiving are not the same thing.

2.) How the question is phrased. A subtle change in the wording will lead the team in a completely different direction.

Shainin’s Approach to Asking Why

At Shainin, we are also interested in asking why, in order to get to the true root cause of problems. Our focus is on perfecting what questions get asked and using the evidence that is available or generated to provide the answers. Some of our clients have described our approach as “refining the art of asking why”.

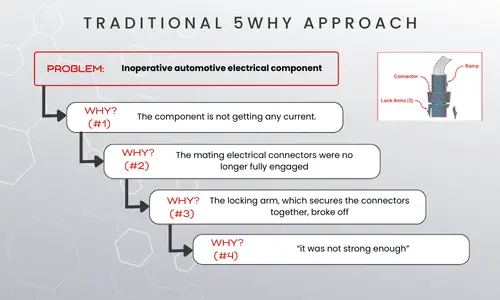

An Example: Electrical Connector Failure

A problem with a broken locking arm on an electrical connector illustrates the typical usage of a 5 Why approach (four whys in this example) and then contrasts it with the Shainin approach. The problem manifested itself as an inoperative automotive electrical component occurring in the field.

Asking WHY (1) revealed that the component was not getting any current. Asking WHY (2) revealed that the mating electrical connectors were no longer fully engaged. Asking WHY (3) again revealed that the locking arm which secures the connectors together had broken off. Asking WHY (4) the locking arm broke, the team answered with “it was not strong enough”.

Limitations of Traditional Problem-Solving

So what corrective actions were available? Most engineers with any experience could develop a list of potential improvements to make the locking arm on the connector stronger; change the material to one which is stronger, increase the wall thickness, increase the fillet radius, etc. This is a very typical approach.

Using this thought process, how do we know if we have identified the “best solution”; that is, the cheapest and easiest to implement, with the lowest risk of creating a new problem? The changes mentioned to strengthen the locking arm are all design changes. Changes to a design which has already been validated involves cost and risk. Is a design change really necessary? Most connectors produced are not failing. Is it possible that a minor process change or perhaps tighter control over a particular parameter could also fix the problem?

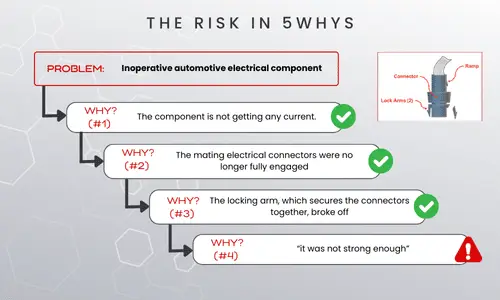

There are many unknowns surrounding this problem, thus there is a risk that the team has walked past a simpler solution beyond the ones proposed. While the first 3 answers to WHY are confirmed through measurements and observation, the fourth one of why the locking arm broke leaves much to be desired.

The team felt that they had to come up with an answer and so they arrived at an obvious conclusion. In fact, the problem is not so much with the answer (the locking arm was not strong enough) but with the question. When conducting a 5 Why investigation, how we phrase the question will very much determine the type of answer we get and ultimately what course of action we take. Shainin methods would provide a more structured approach to these questions.

Refining Questions with Shainin Methods

Before asking why the locking arm broke, we could have asked:

• Was the locking arm subjected to an abusive amount of energy which would have broken any connector?

• Why did the locking arm break in the exact location that it did?

• Why did only 1 out every 100 break?

• Were the failures produced on the same dates?

• Did connectors made in certain mold cavities have a higher failure rate than others?

• Did connectors tested in certain fixtures have a higher failure rate than others?

These questions help us gain further insight into the failure. And while the 5Why questions start to do that, we need more information before we jump to the broader question of “Why did it break”. Once the answer to some of these questions were obtained, then the correct “Why” could be asked.

Discovering the True Root Cause

The team working with their Shainin coach developed a test in order to measure the energy required to replicate the failure mode. After testing samples that were selected from different batches, over different build dates, from different mold cavities and different test fixtures, they learned that there was a significant difference in the strength between some parts coming from the multiple test fixtures.

Each completed wire harness is tested by pressing the electrical connector into a test fixture to ensure electrical connectivity. A pattern was soon observed that connectors that were tested in a specific test fixture were then weaker when evaluating their strength to fail. But what was different with this test fixture as compared to others which did not result in a decrease in part strength. Nothing obvious jumped out.

The team used a Component Search strategy and quickly converged on the key component of the fixture and then the dimensional difference between the best and worst test fixtures. Small cracks were being generated in some locking arms during the electrical check as the connector was inserted into the test fixture, and then propagating in the field under vibratory load.

The corrective action was a minor change to a critical feature of the test fixture, which was interfering with the locking arm, putting unnecessary stress on it as it was engaged during final acceptance testing. No engineering change was necessary.

Implementing Effective Corrective Actions

The key part of this project was asking the right questions. The answers to these new questions revealed previously unknown differences and opportunities. Using Shainin methods, these questions were developed methodically, so that for any technical problem, the appropriate way to ask “Why” will help to uncover the true causes with simple solutions. In fact, we think of Shainin Red X Problem Solving as 5 Why for hidden causes.

Conclusion: Enhancing Problem-Solving with Shainin

5 Why is an effective approach for solving problems where the cause can be discovered through simple observation. But if the result of your investigation does not provide an answer which explains the variation in performance (why are only some of our products failing?), then your solution will not be as targeted as it could be, and instead may involve a design or process change that may be unnecessary.

For these more complex problems where the true cause is hidden, learning to apply the Shainin methods to supplement your 5 Why process will be a worthwhile investment.

About the Author

EXECUTIVE VP - PROBLEM SOLVING

John Abrahamian

John Abrahamian is a highly respected problem solver and an expert in Lean manufacturing, with a career spanning over three decades. Throughout his career, John has become renowned for his innovative problem-solving approach and unwavering dedication to customer satisfaction. His experience in various industries, including aerospace, automotive, medical devices, and consumer products, positions him to effectively guide cross-functional teams through manufacturing and engineering challenges. He holds a Bachelor of Science in mechanical engineering from the University of Connecticut and a Master of Business Administration from Rensselaer Polytechnic Institute.