by John Abrahamian

Better courses. more targeted information.

Part of getting the most return for your investment is making sure that the course your team attends has the right material for their needs. Our new dual path Red X Program allows you to choose the most effective route for your team.

An increasing need for Product Development & Field Performance

For years we have provided guidance for manufacturing and quality engineers focused on problems with end of line product performance, manufacturing scrap, rework, and productivity in mind.

After all that’s where we began. Most projects resulted in tighter control of a critical process parameter. Contained within the manufacturing environment. For years we’ve used those examples in our courses.

It just made sense.

But in recent years, there has been a shift in course attendance. We’re now seeing more engineers from technical centers and design groups looking for tools and strategies to produce better, more reliable products. Engineers and their leaders are in search of a method to enhance their skills, addressing issues with new product development failures, product performance at the consumer level, or field reliability. While the concepts and many of the tools are the same, the strategies are often different. The source of the problem is traced to some component shape or material property within the product.

Following feedback from product engineers, the manufacturing focused training contained some strategies and tools they would rarely use. So we developed a new training path to better focus on their needs.

Which Path to Choose

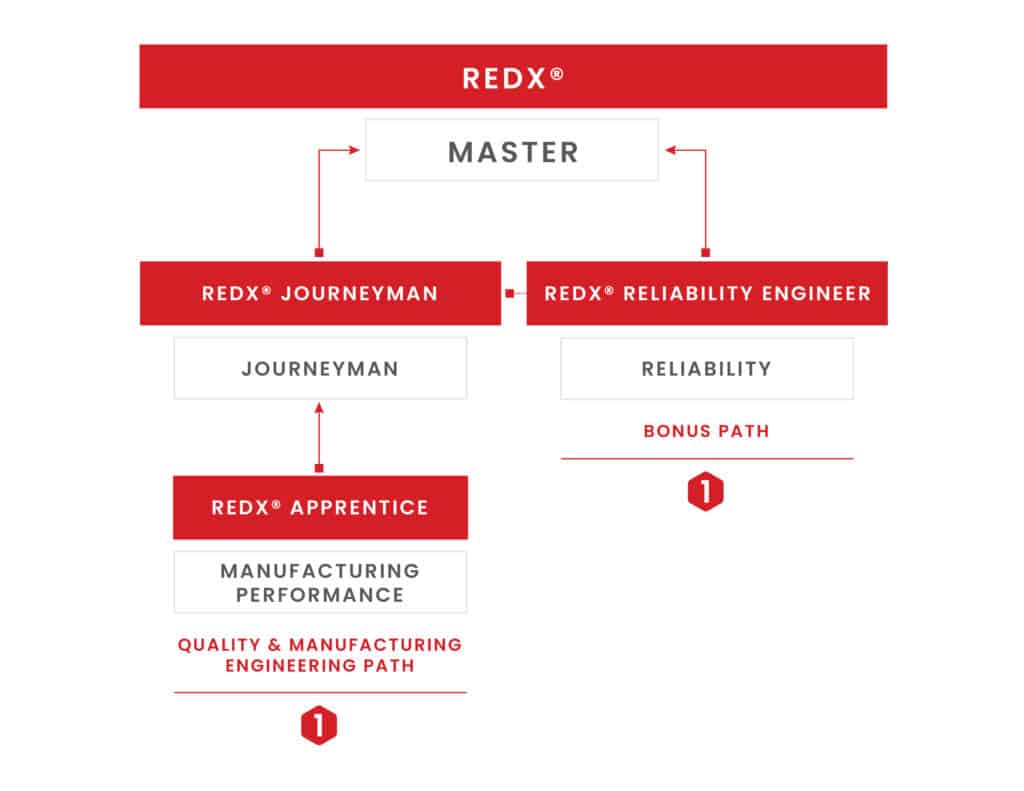

Prior to this change, there was a single Apprentice class which led to the traditional Red X Journeyman course. From there you could progress to Master or take an additional Red X Reliability course. There was no full focus on product development, performance and reliability.

Similar to what you can see in the image here.

Our new structure provides two complete paths: the Quality & Manufacturing Engineering Path or the Product & Reliability Engineering Path.

The Quality & Manufacturing Engineering path remains the same and is best for engineers and their teams who deal directly with production and manufacturing of products.

The Product & Reliability Engineering path is best for teams based in Engineering Technical Centers and engineers that work with warranty projects.

Product & Reliability Path Content

Our Product Performance class introduces concepts, strategies and tools focused on problems encountered during new product development and performance problems occurring in the field. Your product engineers learn advanced strategies for both malfunction and destructive events. Following the successful completion of a project, students will be certified as Red X Apprentices.

Our Reliability Engineer course provides strategies for: recognizing failure patterns; addressing no trouble found; accelerated testing; and understanding fatigue failures. Following the successful completion of a reliability project, your engineers will be certified as Red X Reliability Engineers.

Curriculum Structure to Support Your Team

With this new class structure your engineersacquire the skills to solve a wide range of complex technical problems from early product development, through manufacturing over the life of your products in the field. To learn more about our courses, contact us here.