Why successful problem solving efforts start at the top

As manufacturing continues to face ever-evolving challenges, one thing remains clear: in today’s fast-paced and competitive landscape, companies cannot afford to waste time and resources on unaddressed or unimportant issues; making effective problem solving crucial for sustainable growth and production.

This is where a focused leadership team plays a role in driving success. By aligning their efforts and actively participating in the problem-solving process, leaders can guide their organizations through complex issues and pave the way for long-term success.

In surveys of 106 C-suite executives who represented 91 private and public-sector companies in 17 countries, I found that a full 85% strongly agreed or agreed that their organizations were bad at problem diagnosis, and 87% strongly agreed or agreed that this flaw carried significant costs.

Thomas Wedell-Wedellsborg Source

The Power of Identification: Recognizing Key Problems

As we discussed at length in our prior post in this series, any effective problem-solving journey begins with recognizing and identifying the issue at hand—which oftentimes can be the most challenging. This is where a focused leadership team shines, acting as the organization’s eyes and ears, and becoming adept at isolating noise from critical signals.

Consider this process similar to how a doctor may diagnose an illness. The patient presents a myriad of symptoms, but a skilled doctor—like a focused leadership team—knows which symptoms to hone in on that are indicative of the root cause. They understand that treating the root cause and not the symptoms leads to a healthier patient. Or, in our case, a more robust and efficient organization.

Clear identification of problems not only streamlines the process of finding solutions but also ensures that efforts are not wasted on ‘fire-fighting’ the symptoms while the root cause continues to fester. Remember, clarity in problem identification is a compass that guides the journey to problem-solving success, and it is a focused leadership team that holds this compass steady.

Prioritization: Sorting the Wheat from the Chaff

Following the initial problem identification, the next step is prioritization—especially within an environment as complex as manufacturing, where a myriad of challenges and projects vie for attention and resources.

This is where a focused leadership team demonstrates its strength, astutely separating the ‘vital few’—issues that could make a significant impact on productivity and efficiency—from the ‘trivial many’—issues that might appear important but are not as impactful.

Prioritization enables efficient resource allocation, ensuring that critical problems are not left on the back burner while less consequential issues are addressed. A manufacturing plant grappling with frequent equipment breakdowns and fluctuating market demands should clearly prioritize addressing equipment reliability over market fluctuations, because if the equipment is unreliable, meeting market demands becomes impossible.

And, when different departments have different priorities, a focused leadership team can truly excel in creating alignment across departments by identifying a common metric that all departments can rally around. (Not sure how…? RT5 can help.)

The Art of Focus: Concentrating Efforts for Impactful Solutions

Of course, mastering the art of focus within a leadership team is not only about identifying and prioritizing problems; it’s about channeling resources, expertise, and efforts toward impactful solutions.

Take for example an automobile manufacturing company that adopts a “two birds, one stone” approach when grappling with two issues: high end of line rejection rates of a key component caused by incorrect bores and high scrap rate at the drilling station.

Instead of treating these as separate issues, the leadership might identify a shared project: one that focuses on resolving the issue at the drilling station that creates the scrap and the incorrect bores causing fallout. We essentially get “two birds with one stone”.

These examples underline the power of a focused, team approach to problem-solving. By concentrating efforts on key problems and interconnected solutions, leadership teams can drive meaningful change, create lasting improvements, and contribute to a culture of proactive problem-solving.

Building a Focused Leadership Culture: Steps and Strategies

Building a culture of focused leadership requires several traits, including strategic thinking, effective communication, and unwavering commitment. But instead of getting overwhelmed by the scope of it, let’s delve into actionable steps and strategies that can help foster this culture within your organization.

- Ensure that the vision and goals of your organization are clear and well-communicated. Alignment starts from the top, and clarity in direction helps to foster focus. Use clear and concise language to communicate what the organization’s problem-solving objectives are, why they matter, and how each team contributes to these goals.

- Then get clear about which problems are the top priority. While every problem may seem like a priority, some problems and projects will be more impactful towards accomplishing the goals you’ve outlined in step 1. Keep those goals in mind as your select and prioritize the projects worked on by your teams.

- Adopt the use of multiple problem-solving tools to identify and address the root causes of problems. But more than that, create a guide for when to use which tool and when to shift gears to the next, more advanced tool if progress stalls. These tools can help your team delve deeper into issues and avoid surface-level solutions that do not address the real problem.

- Engage in regular dialogues with your problem-solving teams through daily stand-up meetings or monthly reviews. The goal is to create a feedback-rich environment where ideas can be shared, issues can be aired, and everyone can align their efforts toward common goals.

- Recognize and celebrate problem-solving successes to help sustain momentum and foster a positive problem-solving culture within your team.

Inevitably, you’ll face resistance from some members who are comfortable with the old ways of doing things. Counter this by emphasizing the benefits of a focused leadership approach, like improved efficiency and better resource allocation. Provide training and support, showing them that change, while initially challenging, can lead to significant improvements in the long run.

Results and Return on Investment

Investing in focused leadership for problem-solving can yield significant returns, both in tangible metrics and intangible benefits, just as not investing in the same can produce some steep organizational costs.

In surveys of 106 C-suite executives who represented 91 private and public-sector companies in 17 countries, I found that a full 85% strongly agreed or agreed that their organizations were bad at problem diagnosis, and 87% strongly agreed or agreed that this flaw carried significant costs.

Thomas Wedell-Wedellsborg Source

But more than just quantitative results, a focused leadership approach breeds a culture of innovation and continuous improvement by actively prioritizing and systematically addressing issues. Thus, real-world results underline the substantial return on investment that a focused leadership approach can deliver—not just immediate operational gains, but also a culture of innovation, reputation and reliability with customers, and employee engagement—essential ingredients for sustainable success in today’s competitive manufacturing landscape.

Challenges and Adaptability

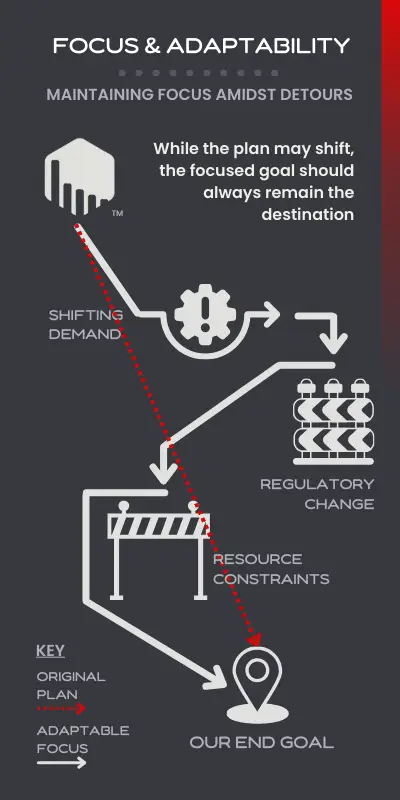

Navigating the waters of manufacturing operations is not a static endeavor; dynamic changes are the order of the day, and maintaining focus amid changing tides can be challenging. The external environment—be it market demands, regulatory changes, or technological advancements—demands continuous adaptation.

And it doesn’t stop there. Shifting priorities and resource constraints necessitate adjustments internally, too. The key to thriving in such a vibrant environment lies in the ability of the leadership team to balance focus with adaptability.

Contrary to some, flexibility does not mean abandoning focus. Rather, it entails adjusting strategies while staying firmly anchored to the core problem-solving objectives. It’s about fine-tuning your sails without losing sight of the destination.

Adaptability in the face of challenges not only showcases the team’s resilience but also encourages a culture of agile problem-solving within the organization. The journey to successful problem solving is not always a straight path; the ability to stay focused amidst detours and disruptions is what ultimately determines your success.

Steering Towards Success

In the demanding world of manufacturing, a focused leadership team is the captain that steers the ship towards problem-solving success. But adopting this approach isn’t a one-time endeavor; it’s a continuous journey toward building a culture of proactive and effective problem-solving.

As leaders, not only do you hold the compass to this journey, but your focus, commitment, and adaptability can spark a problem-solving revolution within your organization. So, take the helm, champion a culture of focused problem-solving, and steer your organization towards a future of sustained success and growth.

As you navigate the complexities of the manufacturing landscape, ask yourself: Are your current problem-solving approaches as effective and focused as they could be? If not, remember that the journey toward fostering such a culture begins with a single step—your decision to champion it.

To get started—as an individual leader or as a team—just reach out to us and start a conversation. As experts in problem solving across industries, we’d be thrilled to help you navigate your own challenges in a better way.

Pingback: Drive Continuous Improvement: Tie Projects to Company Goals